Precision in Every Forging

BELANARO FORGE LLP is a professionally managed manufacturer and exporter of forged bearing rings, automotive components, flanges, and precision-engineered forging parts. Located in Rajkot, Gujarat, India, we serve Europe, the USA, the Middle East, and Asia with high-performance, dimensionally accurate, defect-free forged products.

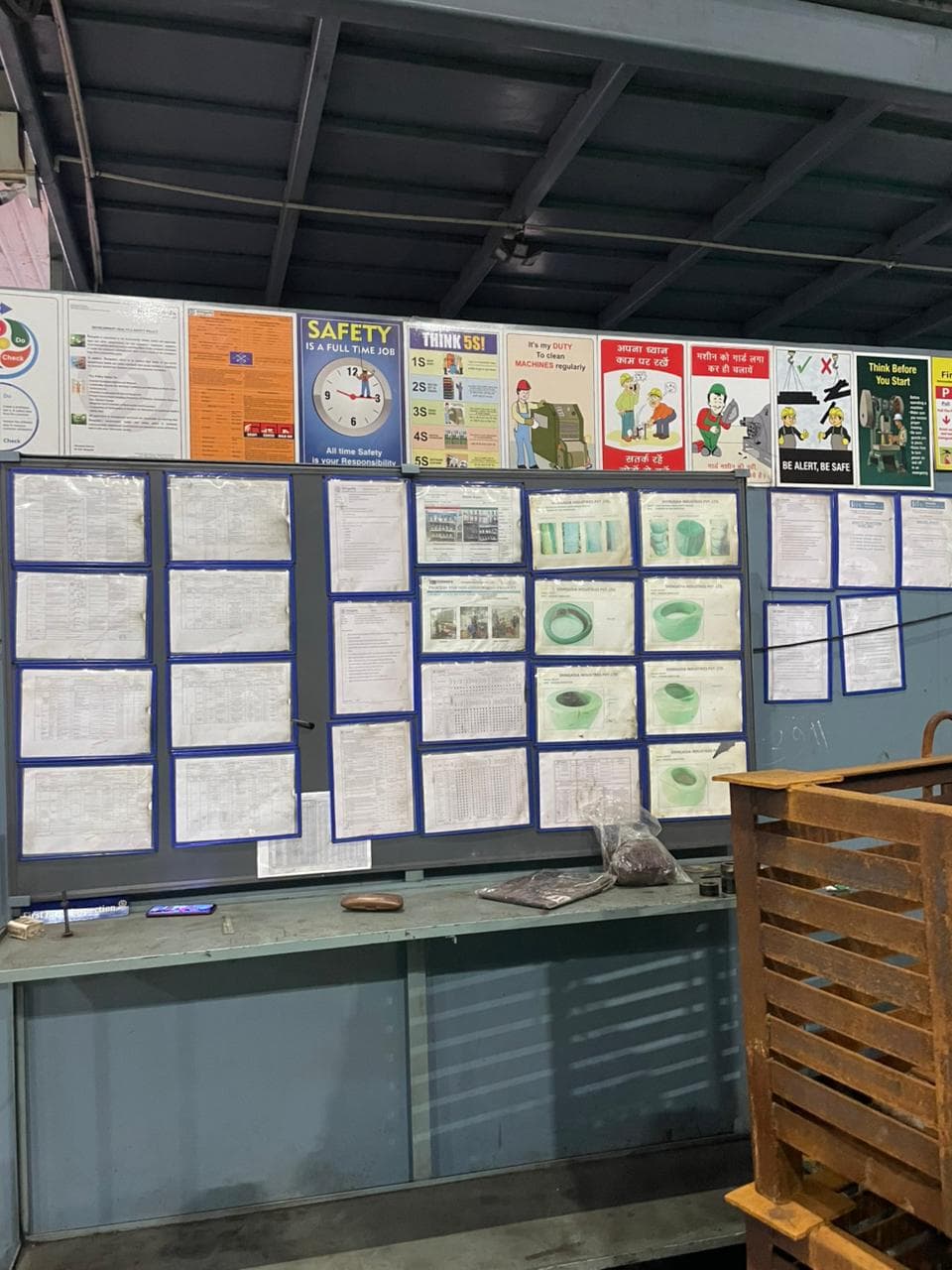

Inside Belanaro Forge LLP

A quick look at our integrated forging facility — from forging bays and machining cells to quality labs that keep every batch traceable.

Forging Highlights

Machining & Tool Room

Quality & Inspection

Company Overview

Since inception, BELANARO FORGE LLP has focused on engineering discipline and manufacturing rigor. We invest in process stability, skilled talent, and quality systems to ensure every forging meets global benchmarks for performance and reliability.

Our integrated ecosystem — from raw material inspection and forging to heat treatment and CNC machining — allows complete traceability and faster time-to-market for both standard and customized parts. This 360° ownership translates into predictable deliveries and repeatable quality.

Key Metrics

- • Diameter range: 25 mm to 500+ mm

- • Prototype to mass production

- • 50 MT/month capacity

- • ISO 9001:2015 systems

Heritage

Built by a team of forging professionals, our culture prioritizes precision, safety, and continuous improvement. We continually modernize equipment and upskill our workforce to stay ahead of demanding application requirements.

Values

- Integrity in commitments and documentation

- Customer-first engineering

- Zero-defect mindset

- Sustainable operations and safe workplace

Materials & Grades

Carbon and alloy steels for strength-critical parts; stainless steels (SS304/SS316) and duplex for corrosion resistance; tool steels for wear-critical dies. Material selection is validated through spectro analysis and heat-treatment trials.

Markets Served

OEMs and importers across Europe, the Middle East, Asia, and the Americas in bearing, automotive, transmission, construction equipment, railways, and general engineering.

FAQs

What drawings do you accept?

STEP/IGES, PDF, and 2D/3D CAD with tolerances and material specifications.

Do you support prototypes?

Yes, from single-piece prototyping to bulk production with the same QA rigor.

Core Strengths

Forged Range of Excellence

We forge and machine components from 25 mm to 500+ mm in diameter, supporting both mass production and custom engineering requirements.

1. Bearing Rings (Inner & Outer)

High roundness accuracy and superior surface finish. Forged, heat-treated, and precision-machined in-house. Ready for direct bearing assembly.

Size Range: 25 mm to 500+ mm • Materials: Carbon, Alloy, Stainless & Duplex Steel

2. Automotive Forgings

Closed-die and ring-rolling forgings designed for optimum mechanical strength and reliability under dynamic loads.

- Steering Knuckles & Suspension Arms

- Differential & Gear Components

- Engine Flanges & Yokes

- Axle Components and Coupling Rings

3. Flanges & Shafts

Industrial and automotive flanges and shafts with perfect concentricity and balance. 100% crack-free and ultrasonic tested.

4. Precision Forged Parts

Custom-engineered precision forgings produced as per client specifications and tolerances with batch-to-batch repeatability.

5. Custom Closed & Open Die Forgings

Bespoke solutions up to 50 kg per piece with controlled grain flow and precise heat treatment for maximum performance.

Manufacturing Excellence

Infrastructure Includes

- Pneumatic Forging Hammers (0.75 – 3 Ton)

- Hydraulic Presses up to 1600 Ton

- Ring Rolling Machines

- CNC Turning & Machining Centers

- Heat Treatment Furnaces

- Tool Room and Measuring Instruments

- Spectrometer & Hardness Tester

Manufacturing Process Flow

- Raw Material Inspection

- Cutting & Billet Preparation

- Forging (Hammer/Press/Ring Rolling)

- Heat Treatment

- Shot Blasting & Grinding

- CNC Machining

- Dimensional & Metallurgical Testing

- Final Inspection & Packing

Quality & Innovation

Zero-defect manufacturing philosophy with multi-stage quality control and international standards compliance.

- Material Composition Testing

- Dimensional Accuracy Check

- Hardness & Metallurgical Testing

- Surface Finish Verification

- Traceable Batch Reports

Global Presence

Exporting to Europe, the Middle East, Asia, and the Americas. Known for timely delivery, product traceability, and transparent communication.

Sustainability & CSR

- Waste heat recovery systems

- Recyclable packaging materials

- Employee safety and skill development programs

Dealership & Partnerships

- Competitive Pricing

- Consistent Supply

- Exclusive Territory Support

- Technical & Marketing Assistance

Contact Information

BELANARO FORGE LLP • Padavala, Veraval-Shapar, Rajkot, Gujarat, India

Phone: +91 8735030126

Email: belanaroforge@gmail.com

Web: www.belanaro.com